G.E. Mathis Company provides the highest quality laser processing services available, offering unmatched precision for a variety of industries and applications.

At G.E. Mathis Company, our precision laser cutting services can be performed on an array of materials and thicknesses, and we can handle a wide range of production volumes. Whether you’re prototyping a new part or ramping up for a high volume run, G.E. Mathis Company can provide end-to-end production services for your laser cutting project.

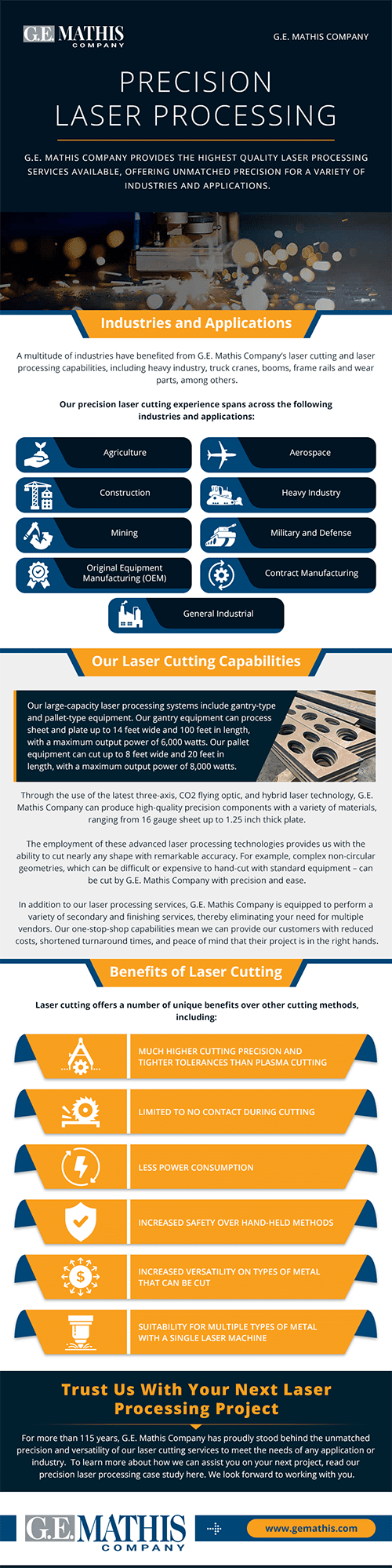

Industries and Applications

A multitude of industries have benefited from G.E. Mathis Company’s laser cutting and laser processing capabilities, including Heavy industry, truck cranes, booms, frame rails and wear parts, among others.

Our precision laser cutting experience spans across the following industries and applications:

- Agriculture

- Aerospace

- Construction / Cranes

- Energy

- Heavy industry

- Mining

- Military and defense

- Trailers / Truck frames

- Original equipment manufacturing (OEM)

- Contract manufacturing

- General industrial

Our Laser Cutting Capabilities

Our large-capacity laser processing systems include gantry-type and pallet-type equipment. Our gantry equipment can process sheet and plate up to 14 feet wide and 100 feet in length, with a maximum output power of 6,000 watts. Our pallet equipment can cut up to 8 feet wide and 20 feet in length, with a maximum output power of 8,000 watts.

Through the use of the latest three-axis, CO2 flying optic, and hybrid laser technology, G.E. Mathis Company can produce high-quality precision components with a variety of materials, ranging from 16 gauge sheet up to 1.25 inch thick plate.

The employment of these advanced laser processing technologies provides us with the ability to cut nearly any shape with remarkable accuracy. For example, complex non-circular geometries, which can be difficult or expensive to hand-cut with standard equipment – can be cut by G.E. Mathis Company with precision and ease.

In addition to our laser processing services, G.E. Mathis Company is equipped to perform a variety of secondary and finishing services, thereby eliminating your need for multiple vendors. Services include CNC plasma cutting, press-brake forming, and welding. Our one-stop-shop capabilities mean we can provide our customers with reduced costs, shortened turnaround times, and peace of mind that their project is in the right hands.

For additional information on G.E. Mathis Company’s precision laser processing services, please click to expand the tables below.

Benefits of Laser Cutting

Laser cutting offers a number of unique benefits over other cutting methods, including:

When cutting sheet metal laser cutting offers several advantages over other cutting methods, including:

- Limited to no contact during cutting

- Less power consumption

- Increased safety over hand-held methods

- Increased versatility on types of metal that can be cut

- Suitability for multiple types of metal with a single laser machine

- Much higher cutting precision and tighter tolerances than plasma cutting

Trust Us With Your Next Laser Processing Project

For more than 110 years, G.E. Mathis Company has proudly stood behind the unmatched precision and versatility of our laser cutting services to meet the needs of any application or industry. To learn more about how we can assist you on your next project, request a quote or contact us today. We look forward to working with you.

Read our precision laser processing case study here.

Request Quote

Please complete the form below and we will contact you shortly.

Over 100+ Years of Experience

Trained & Certified Expertise

Reliable Customer Service