When fabricating components from metal, there are a number of processes that might be suitable. The best method will vary depending on factors such as the type of metal involved and the application’s unique demands. However, laser cutting offers a number of benefits that make it a popular fabrication technique for many industries. This blog post will discuss how laser cutting works and which industries heavily rely on it.

What Is Laser Cutting?

Laser cutting is the process of cutting through metal materials using a focused, high-powered beam of light. It is a highly precise thermal process often recommended in applications requiring tight tolerances, precise cutouts, or holes that are small in relation to the material thickness. This cutting process is ideally suited for many applications.

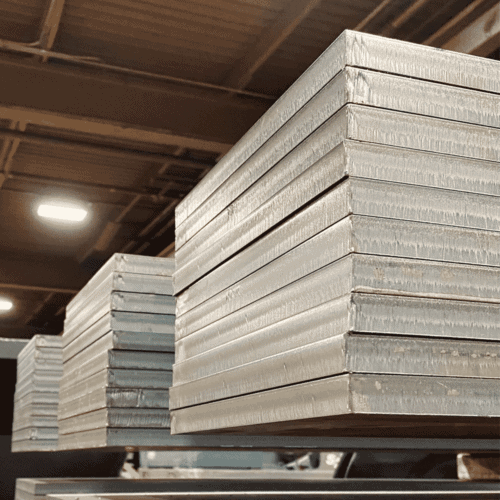

Lasers can cut through metals such as aluminum, stainless steel, and other mild steels with only a small kerf (the material width removed by a cutting process), producing no other damage to the material. Stainless steel laser cutting, in particular, is a popular fabrication process due to the many benefits it provides. Some of the most notable laser cutting advantages include:

- Limited to no physical contact during the cutting process

- Increased worker safety over hand-held cutting methods

- Suitable for a broad range of metal types

- A single laser machine cuts through many types of me

- tal

- Significantly higher cutting precision and tighter tolerances than other methods, such as plasma cutting

Industries that Use Laser Cutting

The versatility of the laser cutting process along with the high degree of precision it provides has led it to be a popular fabrication process in a number of industries. Let’s take a closer look at some of the key industries that rely on laser cutting and how the process is used within those applications.

Agricultural

Laser cutting is a critical process for the agricultural industry, where it is used to produce components for many types of machinery. Equipment such as spreaders, chassis, grain movement components, and tractors are all fabricated using laser cut component parts. In agricultural applications, this process is used to produce most two-dimensional shapes and provides extensive shape production abilities.

Contract Manufacturing

The versatility of laser cutting makes it essential to the contract manufacturing industry, as it can produce components from many different materials in various shapes. The flexibility of laser cutting has made it integral to quickly produce prototype parts, and the accuracy of the laser lends itself to product consistency through repeatability during production runs.

Military

Components used in military applications must meet unique specifications and follow stringent government regulations due to the challenging environments in which they are used. Laser cutting provides the accuracy and reliability necessary to meet these demands and is used to produce a wide variety of components used throughout all branches of the military.

Construction

Laser cutting provides effective, modern solutions for metal part production within construction applications and is transforming the industry. Increasingly, companies are choosing laser cutting fabrication due to its ability to improve production speed and increase operational control and efficiency. Laser cutting is used to produce truck parts, boom tube sections for cranes, and many other components.

G.E. Mathis Company: Reliable Precision Laser Cutting Services

The advantages laser cutting provides over other traditional fabrication techniques have led it to become an essential fabrication method for many industries. For projects involving many types of metal, laser cutting delivers unmatched precision and handles even highly complex designs accurately. In comparison to other metal fabrication techniques, laser cutting reduces lead times and waste materials and can easily accommodate high production volumes.

G.E. Mathis Company specializes in precision laser cutting for demanding industries. Using highly advanced equipment and our 135,000 square-foot production facility, we deliver components tailored to our customers’ exact specifications.

In addition to being an ISO 9001:2015-certified manufacturer, G.E. Mathis Company can provide the following services:

- PPAP (Production Part Approval Process) – All Levels

- FAIR (First Article Inspection Report)

- Capability Studies (Statistical Process Control)

- CMRT (Conflict Minerals Reporting Template)

To learn more about our laser cutting services, contact us today. When you’re ready to get started on a solution, request a quote.