All About Metal Fabrication

Laser Cutting Stainless Steel vs. Plasma Cutting

Should I use Laser cutting or should I use Plasma cutting?

This is a common question that customers ask us. They want to know the difference between the two, and which cutting process is better suited for their application or end-use. While the answer is not always cut and dry, there are some general rules that separate the two processes.

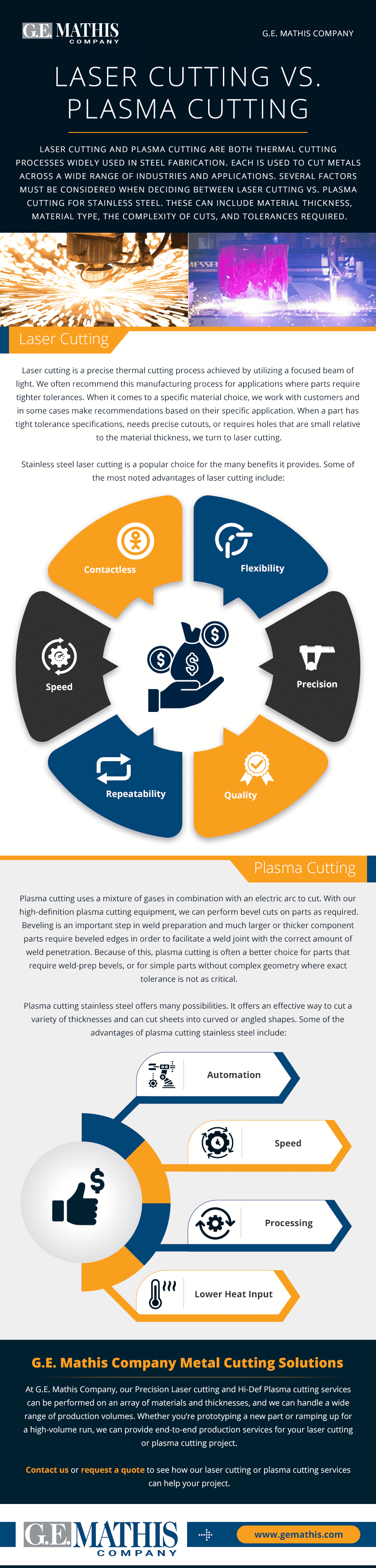

Laser cutting and Plasma cutting are both thermal cutting processes widely used in steel fabrication. Each is used to cut metals across a wide range of industries and applications. Several factors must be considered when deciding between laser cutting vs. plasma cutting for stainless steel. These can include material thickness, material type, the complexity of cuts, and tolerances required.

Each cutting solution has its advantages. Your manufacturer can help determine the best cutting solution for your application, but it is still important to understand the laser cutting and plasma cutting processes and understand the advantages each can provide to help inform your discussion.

Laser Cutting

Stainless steel laser cutting is a popular choice for the many benefits it provides. Some of the most noted advantages of laser cutting include:

- Flexibility. Once a laser is set up and configured for a specific material type and thickness, cuts can be easily repeated on multiple parts, sheets, and plates without the need to change out tools.

- Precision. With general cutting tolerances starting at +/- 0.015”, laser cutting is well suited for precise cuts.

- Quality. Laser cutting produces component parts with greater accuracy than other thermal cutting methods.

- Repeatability. The consistent tight tolerances achieved with laser cutting ensure high repeatability between parts.

- Speed. Laser cutting can be faster than other traditional mechanical cutting processes, especially when making complex or extremely precise cuts.

- Contactless. With laser cutting, there is no mechanical friction to cause wear on tools. Only the laser comes in contact with the material being cut.

Plasma Cutting

Plasma cutting stainless steel offers many possibilities. It offers an effective way to cut a variety of thicknesses and can cut sheets into curved or angled shapes. Some of the advantages of plasma cutting stainless steel include:

- Automation. As a CNC (computer numerical control) cutting process, plasma cutting mitigates the risk of human error over hand-held cutting methods.

- Speed. Plasma cutting cuts as much as five times faster than many comparable cutting methods. The process makes cuts rapidly while simultaneously vaporizing the cut material.

- Processing. Plasma cutting is an ideal method for quickly producing high-quality blanks for medium-to-high thickness Stainless Steel. This cutting method is also good for mild steels of low-to-medium thickness.

- Lower heat input. Plasma cutting can cut extremely hard metals, such as high-strength steel or abrasion-resistant steel, with a lower heat input than other cutting methods.

G.E. Mathis Company Metal Cutting Solutions

The advice listed here should be considered as general rules. At G.E. Mathis Company, we consider which process is best suited to cut each part on a case-by-case basis. We offer both Precision Laser cutting as well as Hi-Definition Plasma cutting options, and also have the experience to help advise you on which is better for your project or application.

At G.E. Mathis Company, our Precision Laser cutting and Hi-Def Plasma cutting services can be performed on an array of materials and thicknesses, and we can handle a wide range of production volumes. Whether you’re prototyping a new part or ramping up for a high-volume run, we can provide end-to-end production services for your laser cutting or plasma cutting project.

In addition to being an ISO 9001:2015-certified manufacturer, G.E. Mathis Company can provide the following services:

- PPAP (Production Part Approval Process) – All Levels

- FAIR (First Article Inspection Report)

- Capability Studies (Statistical Process Control)

- CMRT (Conflict Minerals Reporting Template)

Contact us or request a quote to see how our laser cutting or plasma cutting services can help your project.

Laser Cutting Vs. Plasma Cutting

“Should I use laser cutting or should I use plasma cutting?”—that is the question. Certainly for manufacturers like us, this is a question we receive from many customers; what is the difference between the two and which cutting process is better suited for their end application? While the answer is not cut and dry, there are some general rules that separate the two processes.

For parts that have simple shapes, without many cutouts or intricate notching, we typically utilize plasma cutting. When a part has tight tolerance specifications, needs a precise cut, and/or calls for a small hole diameter in relation to the thickness of the material, then we utilize laser cutting. Again, these are general rules and we consider which process is best suited to cut each part on a case by case basis.

Now, hopefully you have a better understanding of whether laser cutting or plasma cutting is better suited for your application. If not, let us help determine the right cutting process for your parts!

For more information, feel free to contact us today or request a quote for your next project.