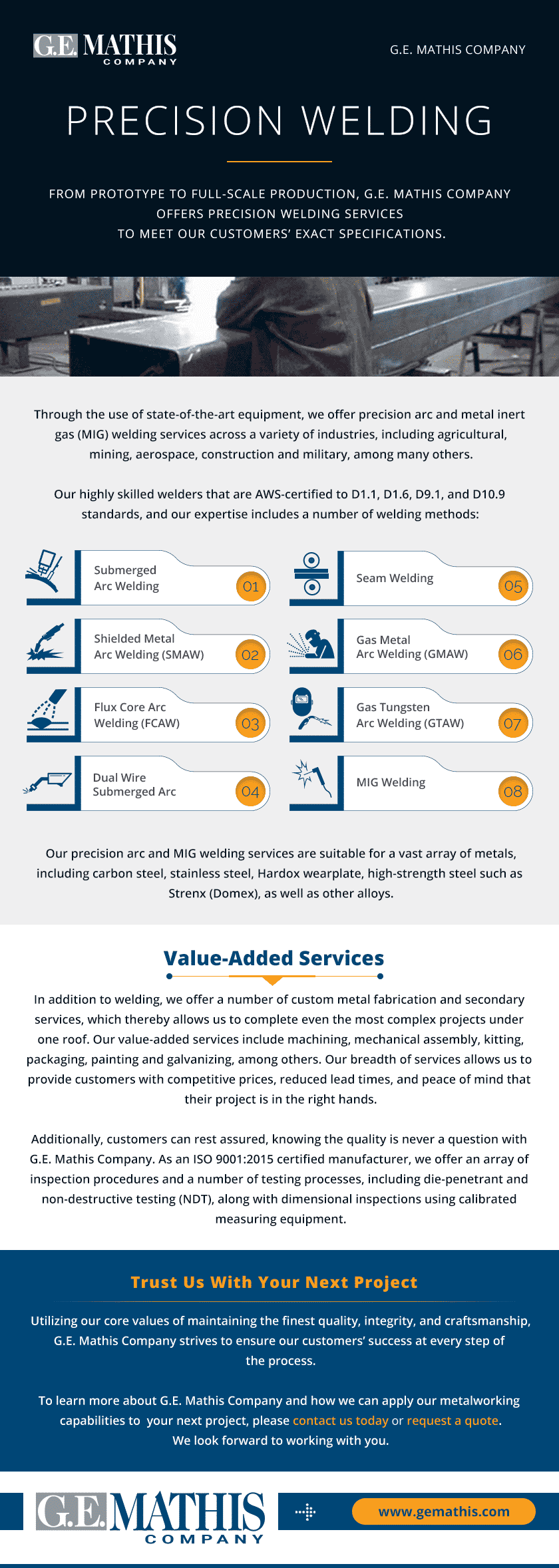

From prototype to full-scale production, G.E. Mathis Company offers precision welding services to meet our customers’ exact specifications.

Through the use of state-of-the-art equipment, we offer precision arc and metal inert gas (MIG) welding services across a variety of industries, including agricultural, mining, aerospace, construction and military, among many others.

Through the use of state-of-the-art equipment, we offer precision arc and metal inert gas (MIG) welding services across a variety of industries, including agricultural, mining, aerospace, construction and military, among many others.

Our highly skilled welders that are AWS-certified to D1.1, D1.6, D9.1, and D10.9 standards.

In addition, G.E. Mathis Company has a Certified Welding Inspector (CWI) on staff.

Our expertise includes a number of welding methods:

- Submerged arc welding

- Seam welding

- Shielded metal arc welding (SMAW)

- Gas metal arc welding (GMAW): MIG welding

- Flux core arc welding (FCAW)

- Gas tungsten arc welding (GTAW)

- Dual wire submerged arc/MIG welding

Our precision arc and MIG welding services are suitable for a vast array of metals, including carbon steel, stainless steel, HARDOX® Wearplate, high-strength steel such as STRENX® Performance Steel (Domex®), as well as other alloys.

For high-precision and large-scale projects, we offer fully automated and CNC-controlled welding services, capable of handling virtually any customer specification. Located in Chicago, Illinois, our 135,000 square foot facility can accommodate large weldments (up to 12 ft wide or 50 ft long), while maintaining the tightest tolerances available in the industry.

Value-Added Services

In addition to welding, we offer a number of custom metal fabrication services, which allow us to complete even the most complex projects under one roof. Our value-added services include CNC laser cutting, CNC plasma cutting, press-brake forming, machining, mechanical assembly, kitting, packaging, painting and galvanizing, among others. Our breadth of services allows us to provide customers with competitive prices, reduced lead times, and peace of mind that their project is in the right hands.

Additionally, customers can rest assured, knowing the quality is never a question with G.E. Mathis Company. As an ISO 9001:2015 certified manufacturer, we offer an array of inspection procedures and a number of testing processes, including die-penetrant and non-destructive testing (NDT), along with dimensional inspections using calibrated measuring equipment.

For more information on G.E. Mathis Company’s precision welding capabilities, please click to expand the tables below.

Trust Us With Your Next Project

Utilizing our core values of maintaining the finest quality, integrity, and craftsmanship, G.E. Mathis Company strives to ensure our customers’ success at every step of the process.

In addition to being an ISO 9001:2015-certified manufacturer, G.E. Mathis Company can provide the following services:

- PPAP (Production Part Approval Process) – All Levels

- FAIR (First Article Inspection Report)

- Capability Studies (Statistical Process Control)

- CMRT (Conflict Minerals Reporting Template)

To learn more about G.E. Mathis Company and how we can apply our metalworking capabilities to your next project, please contact us today. We look forward to working with you.

Request Quote

Please complete the form below and we will contact you shortly.

Over 100+ Years of Experience

Trained & Certified Expertise

Reliable Customer Service